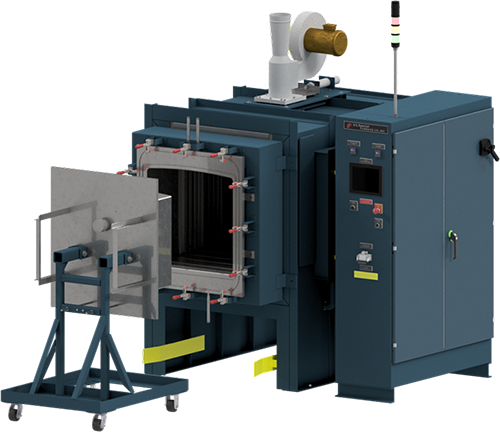

XLC Series Electric Retort Furnace

The XLC series electric furnaces reach a max temperature of 2,000°F (1,094°C). These small to medium-sized furnaces are designed for high-temperature heat-treating processes with atmosphere control, offering uniform heating and advanced controls inside of a gas-tight retort. The XLC series is ideal for demanding industrial applications requiring precise temperature management and reliability.

- Power Type:Electric

- Available Models:14

- Customizable: Yes

What Makes the XLC Series Unique?

The XLC Series Series Electric Retort Furnace is designed to deliver unmatched performance and reliability for a variety of demanding heat-treating processes.

- Alloy Retort •

- This furnace features an alloy retort designed to contain the atmosphere, preventing oxygen infiltration and ensuring a very low dew point for cleaner, safer processing. Depending on size and temperature, the retort can be “D” shaped or corrugated for added strength, and is typically made from 330 Stainless Steel, Inconel 600, or Inconel 601, with other alloys available for specific applications.

- Combustible Atmospheres •

- This furnace is designed to operate in environments ranging from inert up to 100% hydrogen, enabling oxygen-free processing for sensitive parts. This capability ensures cleaner results and is ideal for applications that require a controlled, reducing atmosphere.

- Complete Safety System •

- Equipped with a comprehensive safety system, this furnace ensures safe operation when using combustible atmosphere. This built-in safety feature provides reliable protection, making it suitable for processes requiring stringent safety standards.

- Ceramic Element Holders •

- Proprietary high-temperature ceramic holders provide secure support for the heating elements, enhancing their radiating efficiency and longevity. The smooth surface prevents premature failure from thermal expansion, while the evenly spaced elements ensure superior temperature uniformity throughout the heating chamber.

Comprehensive Features for Optimal Performance

The XLC Series comes equipped with a robust set of standard features, carefully selected to ensure efficient and reliable heat treatment processes. For more specialized applications, optional features are available to enhance the machines capabilities and meet your specific requirements.

Standard Features

All standard features included on XLC Series

- Furnace Type

- Box

- Chamber Size

- Medium

- Max Temperature

- 2000ºF / 1094ºC

- Chambers

- Single

- Chamber Circulation

- Natural Convection

- Chamber Insulation

- Firebrick

- Roof Insulation for Chamber Wider than 24 inches

- Ceramic Fiber Modules

- Door Type

- Retort Plug Cart

- Door Closure

- Manual Threaded Clamps

- Element Type

- Kanthal A1

- Atmosphere Type

- Inert

- Atmosphere Seal

- Gas Tight

- Atmosphere Control

- Manual Rotameter

- Retort

- Yes

- Retort Orientation

- Horizontal

- Control Panel Type

- Free Standing

- Control Voltage

- 120 VAC

- Temperature Controller

- Single Temperature

- Element Power Controller

- Solid State Relay

Optional / Upgrade Features

Optional and upgraded features available on XLC Series

- Door Type

- Retort Plug Swing

- Door Closure

- Manual Toggle Clamps, Pneumatic Toggle Clamps

- Element Type

- Kanthal APM, Nichrome, APM Rod Overbend

- Atmosphere Control

- Automatic Rotameter, Mass Flow Control

- Control Voltage

- 24 VDC

- Temperature Controller

- Basic Programmer, Advanced Programmer, PLC

- AMS Compliance

- AMS2750

- Data Recorder

- Addon

- Signal Tower

- Addon

- Forced Air Cooler

- Addon

- High Powered Heating Elements

- Addon

- Loading/Unloading System

- Roller Hearth, Manual Charge Table, Manual Fork Loader, Electric Fork Loader, Internal Shelving

- Element Power Controller

- Digital SCR Control

- Heat Shields

- Addon

- Atmosphere Type

- Combustible

XLC Series Standard Model Sizes

The XLC Series is available in a range of standard sizes to accommodate various load dimensions and production requirements. As with most L&L furnaces, custom sizes are available upon request. To inquire about custom sizes, please contact our sales team .

| Model Name | Working Dimensions | Interior Dimensions | Exterior Dimensions | Max Power | Max Load | Total Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W | H | D | W | H | D | W | H | D | kW | Lbs | Lbs | |

| XLC 524 | 10 | 10 | 22 | 16 | 18 | 25 | 54 | 59 | 48 | 14 | 50 | 1,500 |

| XLC 824 | 12 | 12 | 22 | 19 | 21 | 25 | 57 | 62 | 48 | 17 | 75 | 1,800 |

| XLC 836 | 12 | 12 | 34 | 19 | 21 | 37 | 57 | 62 | 60 | 23 | 100 | 2,100 |

| XLC 848 | 12 | 12 | 46 | 19 | 21 | 49 | 57 | 62 | 72 | 27 | 150 | 2,400 |

| XLC 244 | 18 | 18 | 22 | 25 | 27 | 25 | 63 | 68 | 48 | 24 | 100 | 2,600 |

| XLC 246 | 18 | 18 | 34 | 25 | 27 | 37 | 63 | 68 | 60 | 32 | 175 | 3,000 |

| XLC 248 | 18 | 18 | 46 | 25 | 27 | 49 | 63 | 68 | 72 | 38 | 225 | 3,500 |

| XLC 272 | 18 | 18 | 70 | 25 | 27 | 73 | 63 | 68 | 96 | 51 | 350 | 4,000 |

| XLC 3348 | 24 | 24 | 46 | 31 | 33 | 49 | 69 | 74 | 72 | 49 | 275 | 3,800 |

| XLC 3372 | 24 | 24 | 70 | 31 | 33 | 73 | 69 | 74 | 96 | 67 | 400 | 5,500 |

| XLC 3448 | 30 | 18 | 46 | 37 | 27 | 49 | 75 | 68 | 72 | 48 | 350 | 4,000 |

| XLC 3472 | 30 | 18 | 70 | 37 | 27 | 73 | 75 | 68 | 96 | 66 | 550 | 6,000 |

| XLC 3648 | 30 | 30 | 46 | 37 | 39 | 49 | 75 | 80 | 72 | 46 | 350 | 4,800 |

| XLC 3672 | 30 | 30 | 70 | 37 | 39 | 73 | 75 | 80 | 96 | 82 | 550 | 7,000 |

Interested in working with us?

Sometimes it is easier to talk to someone directly. Provide us basic contact information. We'll be in touch