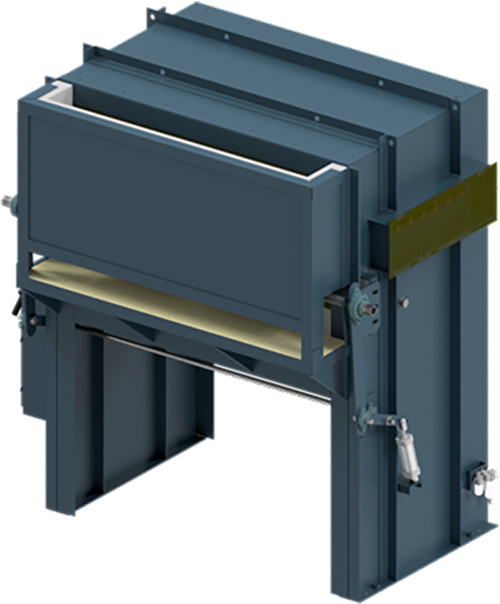

FWE Series Electric Forging Furnace

The FWE series electric forge furnaces operate at temperatures up to 2,200°F (1,204°C). These medium to large-sized furnaces are designed to be used in steel forging applications. The FWE series provides advanced temperature control systems and is built for long-term durability, ensuring consistent results in demanding processes.

- Power Type:Electric

- Available Models:7

- Customizable: Yes

What Makes the FWE Series Unique?

The FWE Series Series Electric Forging Furnace is designed to deliver unmatched performance and reliability for a variety of demanding heat-treating processes.

- Multiple Applications •

- The FWE series is perfectly suited for forging applications in both the medical and automotive industries. Its precise temperature control and robust construction make it ideal for producing high-quality components with exacting standards.

- Selectable Door Height •

- The door opening height can be adjusted to either full height or a smaller slot, providing flexibility for different loading requirements. This feature enhances operational efficiency and safety, allowing for easy access and controlled atmosphere retention during loading and unloading.

- Ceramic Element Holders •

- Proprietary high-temperature ceramic holders provide secure support for the heating elements, enhancing their radiating efficiency and longevity. The smooth surface prevents premature failure from thermal expansion, while the evenly spaced elements ensure superior temperature uniformity throughout the heating chamber.

Comprehensive Features for Optimal Performance

The FWE Series comes equipped with a robust set of standard features, carefully selected to ensure efficient and reliable heat treatment processes. For more specialized applications, optional features are available to enhance the machines capabilities and meet your specific requirements.

Standard Features

All standard features included on FWE Series

- Furnace Type

- Box

- Chamber Size

- Medium - Large

- Max Temperature

- 2200ºF / 1204ºC

- Chambers

- Single

- Chamber Circulation

- Natural Convection

- Insulation Type

- Ceramic Fiber Modules

- Door Type

- Vertical (Electric)

- Element Type

- APM Rod Overbend

- Hearth Type

- Firebrick Floor

- Atmosphere Type

- Ambient Air

- Control Panel Type

- Side Mounted

- Control Voltage

- 120 VAC

- Temperature Controller

- Single Temperature

- Element Power Controller

- Solid State Relay

Optional / Upgrade Features

Optional and upgraded features available on FWE Series

- Door Type

- Vertical (Pneumatic)

- Element Type

- Silicon Carbide

- Hearth Type

- Ceramic Plate, Alloy Plate, Castable Floor

- Hearth Support

- Ceramic Standoffs, Firebrick Piers, Castable Piers

- Control Panel Type

- Free Standing

- Control Voltage

- 24 VDC

- Temperature Controller

- Basic Programmer, Advanced Programmer

- Data Recorder

- Addon

- Signal Tower

- Addon

- High Powered Heating Elements

- Addon

FWE Series Standard Model Sizes

The FWE Series is available in a range of standard sizes to accommodate various load dimensions and production requirements. As with most L&L furnaces, custom sizes are available upon request. To inquire about custom sizes, please contact our sales team .

| Model Name | Working Dimensions | Interior Dimensions | Exterior Dimensions | Max Power | Max Load | Total Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W | H | D | W | H | D | W | H | D | kW | Lbs | Lbs | |

| FWE 222 | 24 | 24 | 24 | 30 | 35 | 28 | 74 | 118 | 86 | 60 | 600 | 2,900 |

| FWE 224 | 24 | 24 | 48 | 30 | 35 | 52 | 74 | 118 | 110 | 120 | 1,200 | 3,500 |

| FWE 333 | 36 | 36 | 36 | 42 | 47 | 40 | 98 | 144 | 98 | 175 | 1,350 | 4,500 |

| FWE 334 | 36 | 36 | 48 | 42 | 47 | 52 | 98 | 144 | 110 | 205 | 1,800 | 5,500 |

| FWE 336 | 36 | 36 | 72 | 42 | 47 | 76 | 98 | 144 | 134 | 235 | 2,700 | 6,500 |

| FWE 444 | 48 | 48 | 48 | 54 | 59 | 52 | 110 | 178 | 110 | 265 | 2,400 | 8,000 |

| FWE 446 | 48 | 48 | 72 | 54 | 59 | 76 | 110 | 178 | 134 | 365 | 3,600 | 10,000 |

Interested in working with us?

Sometimes it is easier to talk to someone directly. Provide us basic contact information. We'll be in touch