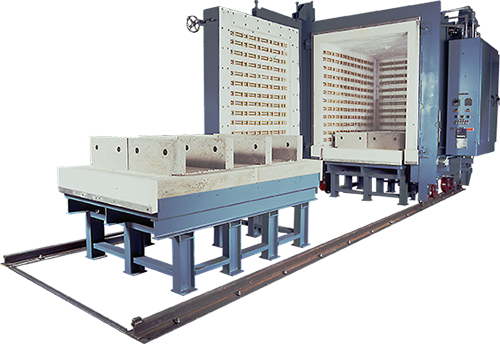

FS Series Electric Shuttle Furnace

The FS series shuttle furnaces reach a max temperature of 2,200°F (1,204°C). Built for handling large loads, the FS series is ideal for heavy-duty industrial parts and components. Its rolling heating chamber allows for easy loading and unloading, making it a popular choice for high-volume production processes where efficiency and uniform heating are essential. The FS series is commonly used in the Aerospace and Automotive industries but is flexible enough to be used in a wide variety of applications.

- Power Type:Electric

- Available Models:6

- Customizable: Yes

What Makes the FS Series Unique?

The FS Series Series Electric Shuttle Furnace is designed to deliver unmatched performance and reliability for a variety of demanding heat-treating processes.

- Large Work Zone •

- With its spacious work zone, this furnace is perfect for processing larger parts or accommodating multiple smaller components in a single cycle. This versatility increases productivity and efficiency for a wide range of heat treatment applications.

- Process Flexibility •

- This furnace series can be customized to meet specific process and part requirements, offering tailored solutions for unique heat treatment needs. This flexibility ensures optimal performance and efficiency, regardless of your application.

- Movable Chamber •

- The electrically driven movable heating chamber allows for effortless side or overhead loading and unloading of parts. This feature enhances operational efficiency and safety, making it ideal for handling large or heavy components with ease.

- Ceramic Element Holders •

- Proprietary high-temperature ceramic holders provide secure support for the heating elements, enhancing their radiating efficiency and longevity. The smooth surface prevents premature failure from thermal expansion, while the evenly spaced elements ensure superior temperature uniformity throughout the heating chamber.

Comprehensive Features for Optimal Performance

The FS Series comes equipped with a robust set of standard features, carefully selected to ensure efficient and reliable heat treatment processes. For more specialized applications, optional features are available to enhance the machines capabilities and meet your specific requirements.

Standard Features

All standard features included on FS Series

- Furnace Type

- Shuttle

- Chamber Size

- Large - Extra Large

- Max Temperature

- 2200ºF / 1204ºC

- Chambers

- Single

- Chamber Circulation

- Natural Convection

- Insulation Type

- Ceramic Fiber Modules

- Door Type

- Horizontal

- Door Closure

- Manual Threaded Clamps

- Element Type

- Kanthal A1

- Hearth Support

- Castable Piers

- Atmosphere Type

- Ambient Air

- Control Panel Type

- Free Standing

- Control Voltage

- 120 VAC

- Temperature Controller

- Single Temperature

- Element Power Controller

- Solid State Relay

Optional / Upgrade Features

Optional and upgraded features available on FS Series

- Chamber Circulation

- Circulation Fan

- Door Closure

- Pneumatic Toggle Clamps

- Element Type

- Kanthal APM, Nichrome

- Hearth Type

- Ceramic Plate, Alloy Plate, Firebrick Floor, Castable Floor

- Atmosphere Type

- Inert

- Atmosphere Seal

- Basic

- Atmosphere Control

- Manual Rotameter, Automatic Rotameter, Mass Flow Control

- Control Voltage

- 24 VDC

- Temperature Controller

- Basic Programmer, Advanced Programmer, PLC

- AMS Compliance

- AMS2750

- Data Recorder

- Addon

- Signal Tower

- Addon

- Forced Air Cooler

- Addon

- High Powered Heating Elements

- Addon

- Loading/Unloading System

- Roller Hearth, Manual Charge Table, Internal Shelving

- Element Power Controller

- Digital SCR Control

- Heat Shields

- Addon

FS Series Standard Model Sizes

The FS Series is available in a range of standard sizes to accommodate various load dimensions and production requirements. As with most L&L furnaces, custom sizes are available upon request. To inquire about custom sizes, please contact our sales team .

| Model Name | Working Dimensions | Interior Dimensions | Exterior Dimensions | Max Power | Max Load | Total Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W | H | D | W | H | D | W | H | D | kW | Lbs | Lbs | |

| FS 224 | 30 | 48 | 48 | 38 | 54 | 56 | 88 | 92 | 80 | 86 | 750 | 7,400 |

| FS 246 | 30 | 48 | 72 | 38 | 54 | 80 | 88 | 92 | 104 | 113 | 1,125 | 9,300 |

| FS 2412 | 30 | 48 | 144 | 38 | 54 | 152 | 88 | 92 | 176 | 192 | 2,250 | 15,300 |

| FS 2424 | 30 | 48 | 288 | 38 | 54 | 296 | 88 | 92 | 320 | 351 | 4,500 | 27,200 |

| FS 4512 | 48 | 60 | 144 | 56 | 66 | 152 | 106 | 104 | 176 | 267 | 3,600 | 19,600 |

| FS 4524 | 40 | 60 | 288 | 56 | 66 | 296 | 106 | 104 | 320 | 478 | 7,200 | 34,800 |

Interested in working with us?

Sometimes it is easier to talk to someone directly. Provide us basic contact information. We'll be in touch