Product Spotlight: L&L Special Furnace Model VBA For Use With Additive Manufacturing

11/6/2023 • L&L Online Team

Introduction

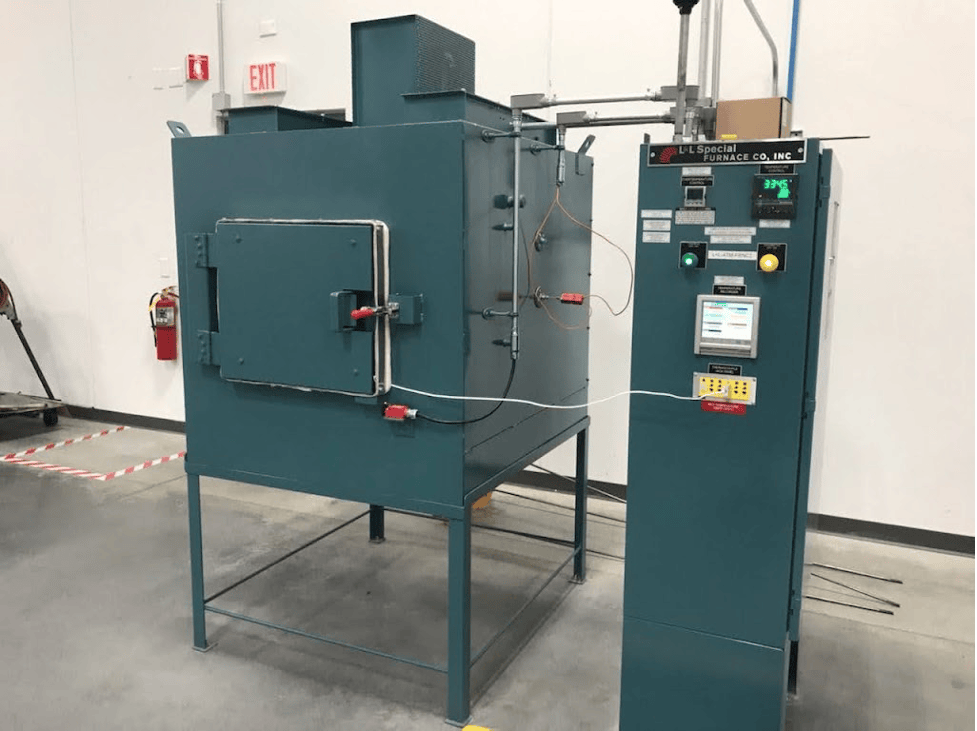

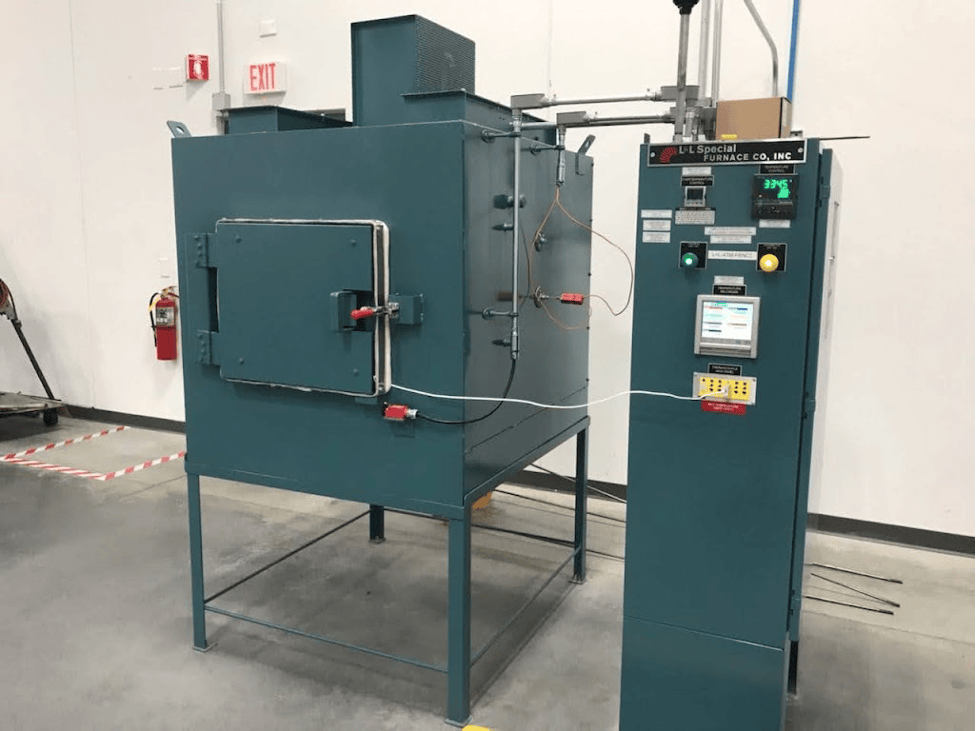

L&L has found that our VB Series Low-Temperature Tempering Oven works best in these applications for stress relieving and tempering AM parts. When configured for tight uniformity, they can achieve AMS2750 Class 2 Uniformity (+/- 10ºF) from 500ºF up to a Maximum Operating Temperature of 1,300ºF.

caption id="attachment_10535" align="aligncenter" width="977" Model VBA1824 Equipped with Pyrometry Package and Interior Baffles for Aluminum Heat-Treating/caption

Model VBA1824 Equipped with Pyrometry Package and Interior Baffles for Aluminum Heat-Treating/caption

About the VB Series

VB Series OvenConstruction

With the VBA option, the chamber has a secondary recirculation baffle that shields the parts from the Incoloy Sheathed Heating Elements. The baffle has cutouts that allow for the air flow from a 12” 3/4HP circulation fan to be directed around the chamber to ensure tight uniformity.

Controls

L&L prefers to always deploy a stand-alone Overtemperature Controller. For this project, we used a Eurotherm 3216i FM-Approved Limit Controller. Other configurations and controller makes are available to standardize on a specific customer’s needs.

To achieve AMS2750 Type A Instrumentation, the Pyrometry package included Thermocouple Ports at all (8) Corners of the Work Zone, (3) Load Thermocouples, and a (6) Input Chessel 6100A Data Recorder. All of the Control Instrumentation was Type N while the Load Thermocouples were Type K.

Some custom logic was added between the Data Recorder and Temperature Controller. These devices were set up so that the Data Recorder feeds the average reading of however many Load Thermocouples are connected (the Recorder is smart enough to know how many Sensors are connected) into the Temperature Controller.

The Temperature Controller is set up so that the Soak Segments will not begin counting until the Load Thermocouples are within spec. This is different from a typical “Guaranteed Soak” in that it does not rely on the Control Thermocouple (which measures the temperature of the air inside the chamber), instead using Load Thermocouples that are placed directly on the parts.

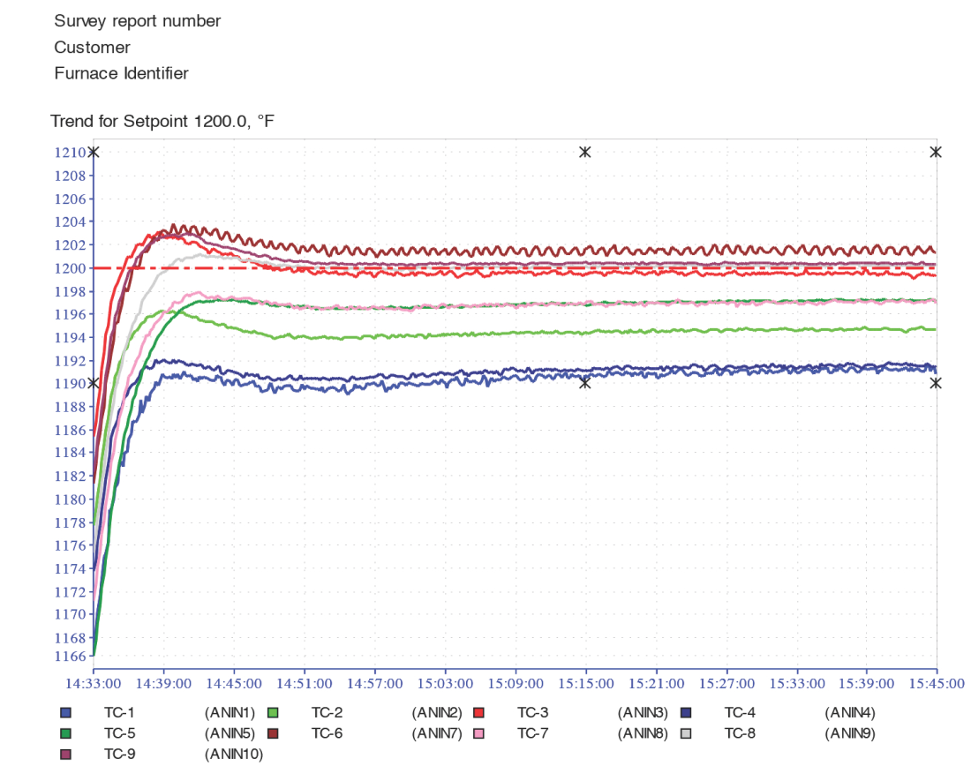

Lastly, the Oven was tested based on AMS2750 Initial TUS requirements to ensure +/-10ºF uniformity. The uniformity was surveyed at 500ºF, 575ºF, 800ºF and 1,200ºF. The testing was performed with L&L’s in-house Eurotherm 6100A TUS Recorder. Prior to shipping the Furnace, we were able to demonstrate that the Oven Uniformity was within the Class 2 Requirement. The final TUS was performed by Aerospace Testing and Pyrometry, Inc., after the Oven was installed.

caption id="attachment_10536" align="aligncenter" width="972" TUS Chart of VBA1824 Oven with 1,200ºF Setpoint/caption

TUS Chart of VBA1824 Oven with 1,200ºF Setpoint/caption

Additional information about our VB Series Tempering Oven can be found on our website at: https://llfurnace.com/series/vb/. Alternatively, our Sales Team can be reached directly at sales@llfurnace.com.

We hope you found this article informative and engaging. At L&L Special Furnace, we are dedicated to providing high-quality industrial furnace solutions tailored to meet your specific needs. With decades of experience and a commitment to innovation, we strive to deliver exceptional products and services to our valued customers.

For more information about our products, visit our Series page. Need help with your current heat treating solution? Contact us today to speak with an expert who can help.

Interested in working with us?

Sometimes it is easier to talk to someone directly. Provide us basic contact information. We'll be in touch