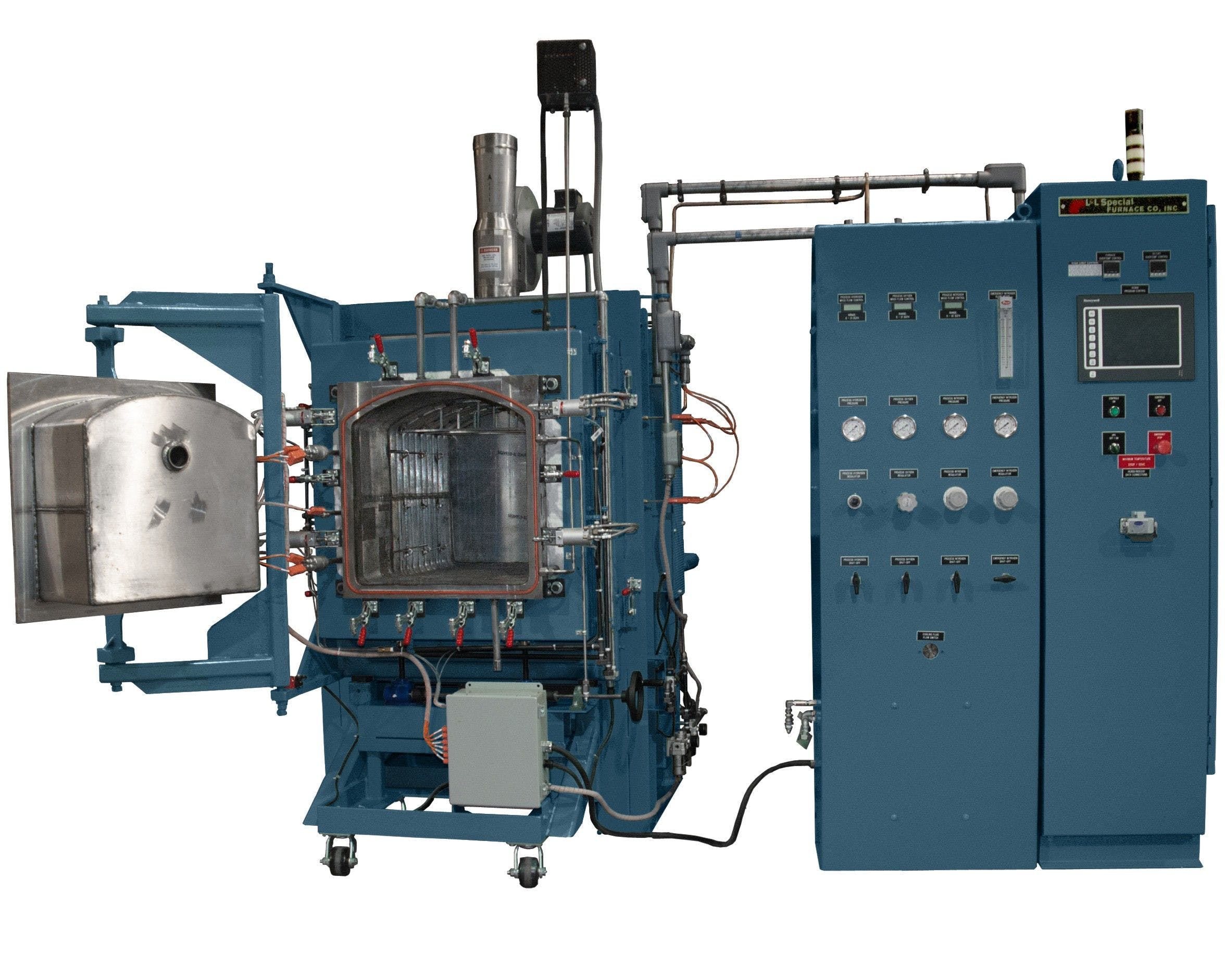

Press Release: L&L Special Furnace Ships Retort Furnace To Motor Manufacturer Used For Heat Treating Motor Laminations

6/20/2023 • L&L Online Team

L&L Special Furnace has shipped a model XLC3348 retort furnace with an Inconel 602CA alloy retort to a leading manufacturer of motor laminations located in the Midwestern U.S. The furnace serves a primary role in the manufacturing of motor laminations in an atmosphere of up to 100% hydrogen. The laminations are deployed for motors in various aerospace, military, automotive, medical, and industrial fields.

The model XLC3348 has an effective work zone of 23” wide by 23” high by 36” deep and uniformity of ±15°F above 1,200°F after optimal tuning and balancing of any gradients using digital biasing. The control system includes one control loop along with six zones of heating volume that can be adjusted to achieve the required temperature gradients.

The furnace is equipped with a controlled cooling system, which is critical to the motor lamination process. L&L also offers retort furnaces with removable retorts to meet the most stringent cooldown requirements.

The model XLC3348 satisfies all requirements for AMS2750F class 3 uniformity and type B instrumentation. The furnace features a water-cooled, front flange and door plug cart for easy handling of the door with guides. Included is a complete gas-mixing panel with independent hydrogen, nitrogen, and emergency nitrogen lines. The process gas lines are required copper refrigeration lines along with stainless steel to ensure a very low dew point in the process gasses, which is critical to the process.

A Honeywell HC900 hybrid PLC-process controller with CR10 operator interface is included and clearly displays the operating state, alarm conditions, and programming aspects of the process logic parameters. This is completely set up, configured, and logic-tested prior to shipment.

The control panel is a floor-standing NEMA12 enclosure with fused disconnect and all required fusing and wiring. The electrical system is designed in compliance with NFPA86 guidelines for safety and includes all required electrical components, placards, and paint schemes.

All L&L furnaces can be configured with various options and be specifically tailored to meet your thermal needs. We also offer furnaces equipped with pyrometry packages to meet the latest revision of AMS2750.

Options include a variety of control and recorder configurations. A three-day, all-inclusive startup service is included with each system within the continental U.S. and Canada. International startup and training service is available by factory quote.

If precise temperature control and uniformity are key to your process, then L&L's XLC series is a great choice. Request a Quote today!

We hope you found this article informative and engaging. At L&L Special Furnace, we are dedicated to providing high-quality industrial furnace solutions tailored to meet your specific needs. With decades of experience and a commitment to innovation, we strive to deliver exceptional products and services to our valued customers.

For more information about our products, visit our Series page. Need help with your current heat treating solution? Contact us today to speak with an expert who can help.

Interested in working with us?

Sometimes it is easier to talk to someone directly. Provide us basic contact information. We'll be in touch