Aluminum Heat Treating

10/28/2018 • L&L Online Team

Since the early days of flight, aluminum in many forms has been used in the manufacture of aircraft. Aluminum is a lightweight structural material that can be strengthened through alloying and, depending upon composition, further strengthened by heat treatment and/or cold working.

Among its advantages for specific applications are low density, high strength-to-weight ratio, good corrosion resistance, ease of fabrication, and diversity of form. These attributes, along with its relatively low material cost, are strong factors that make aluminum the most common material used in both aerospace and automotive industries today.

Heat Treatable Grades of Aluminum

The 2XXX series has copper as its primary alloying element, which gives it additional strength, and is a commonly used aircraft alloy. The 6XXX series include silicon and magnesium in the alloy, which provides even better corrosion resistance that makes it very well adapted for use in automobile production. The 7XXX series includes zinc and magnesium and either chromium or copper. This combination of alloying elements makes extremely high strength possible, and this series is used extensively in the aerospace industry. The 8XXX series are alloyed with iron, silicon, vanadium, and copper. This series is also widely used in aerospace.

Aluminum Alloy Heat Treatment Designations

- F: as fabricated

- 0: annealed, or full soft

- H: strain hardened

- T: thermally treated

Strain hardened aluminum alloys with the H designation typically include one or two more digits. H1 is strain hardened without thermal treatment, H2 is strain hardened and partially annealed, H3 is strain hardened and then stabilized by low temperature heating. The second digit represents the degree of hardness obtained by strain hardening. For example, HX2 is ¼ hard, HX4 is ½ hard, HX6 is ¾ hard, and HX8 is full hard. A designation of HX9 would represent extra hard.

The T designation means that the aluminum has been heat treated to produce a stable temper. The T can appear as TX, TXX, or TXXX, with the digits providing detail as to what heat treatment process and quenches were involved. For example, T6 means solution heat treated and artificially aged, while T4 means solution heat treated and naturally aged.

AMS2750E

AMS2750E (Aerospace Material Specifications)SAE InternationalNadcap

AMS2750E (Aerospace Material Specifications)SAE InternationalNadcapThis specification was written to ensure that critical processes are kept within strict guidelines as delineated in this specification. Norm compliance to the AMS2750E standard means that the quality standard of the components manufactured can be reproduced in series. This is vitally important for components whose failure could not only cost thousands of dollars but could also cost lives.

Factors for AMS2750E Compliance

Naturally, there will be uncertainty in the temperature measurements. The level of uncertainty is a function of the wire used, the design of both the probes and the connectors, the lead wire (if used), the accuracy of the furnace controller, and any algorithms used internally by the controller.

Furnace Requirements for AMS2750E Compliance

Thermocouples must be placed to accurately characterize the heating process and the temperature distribution within the oven. Controllers also play a very key role. And not only does this involve the type and accuracy of the controller, but also any internal algorithms that it uses to either read thermocouple temperatures or control the aluminum heat treating processes within the oven itself.

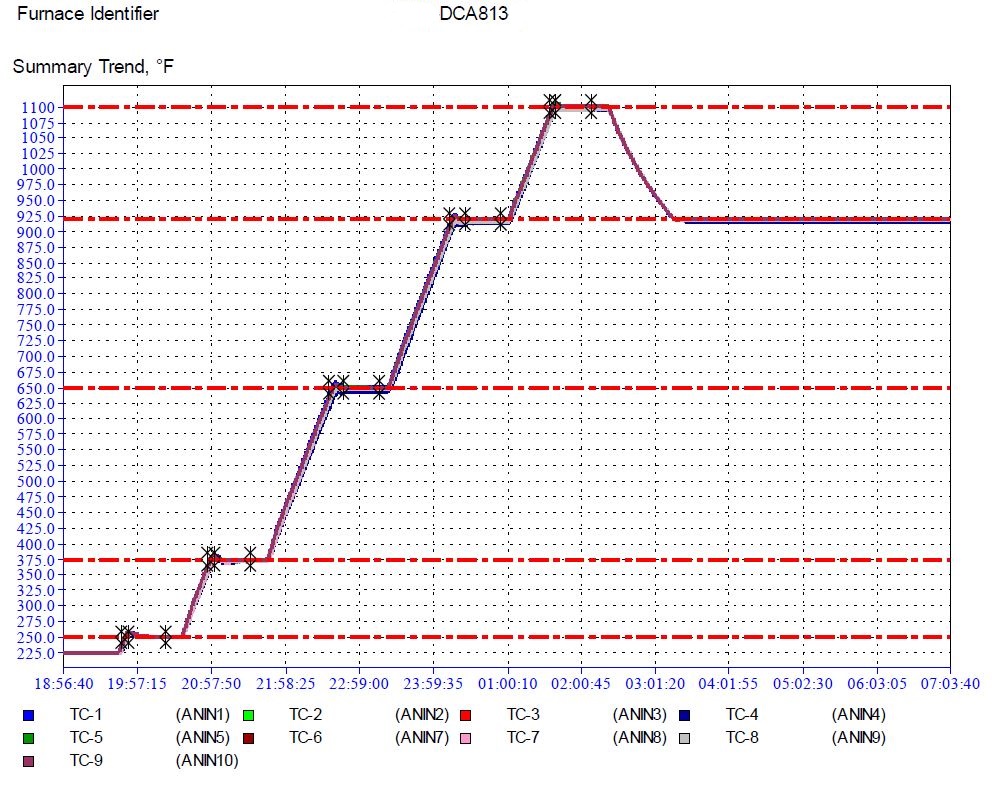

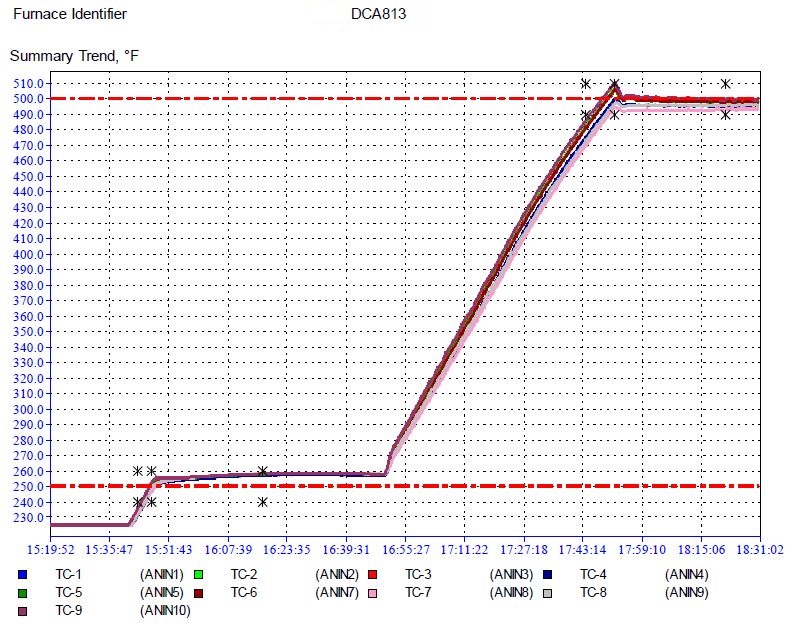

L&L Aviation Pyrometry Package

One of the critical aspects of AMS2750E involves the operation, location, and even selection of thermocouples used for monitoring the temperature distribution inside the oven. L&L provides a thermocouple inlet tube which allows for TUS thermocouples to be inserted into the furnace without compromising the door seal. There are thermocouple reference ports located within 2” of each system thermocouple to perform system accuracy tests (SAT).

There are also thermocouple ports located in the best possible representation of the furnace’s effective work zone. These ports are extremely important and allow for recording of the high and low thermocouple readings as indicated by the most recent temperature uniformity survey (TUS).

All this instrumentation plugs into the main control thermocouple jack panel which in turn is wired to the systems temperature recorder. All data obtained is logged and kept in electronic encrypted format. These files can easily be transferred and shared to analyze the thermal data. L&L’s aviation pyrometry package is a must-have tool for critical temperature processing needs.

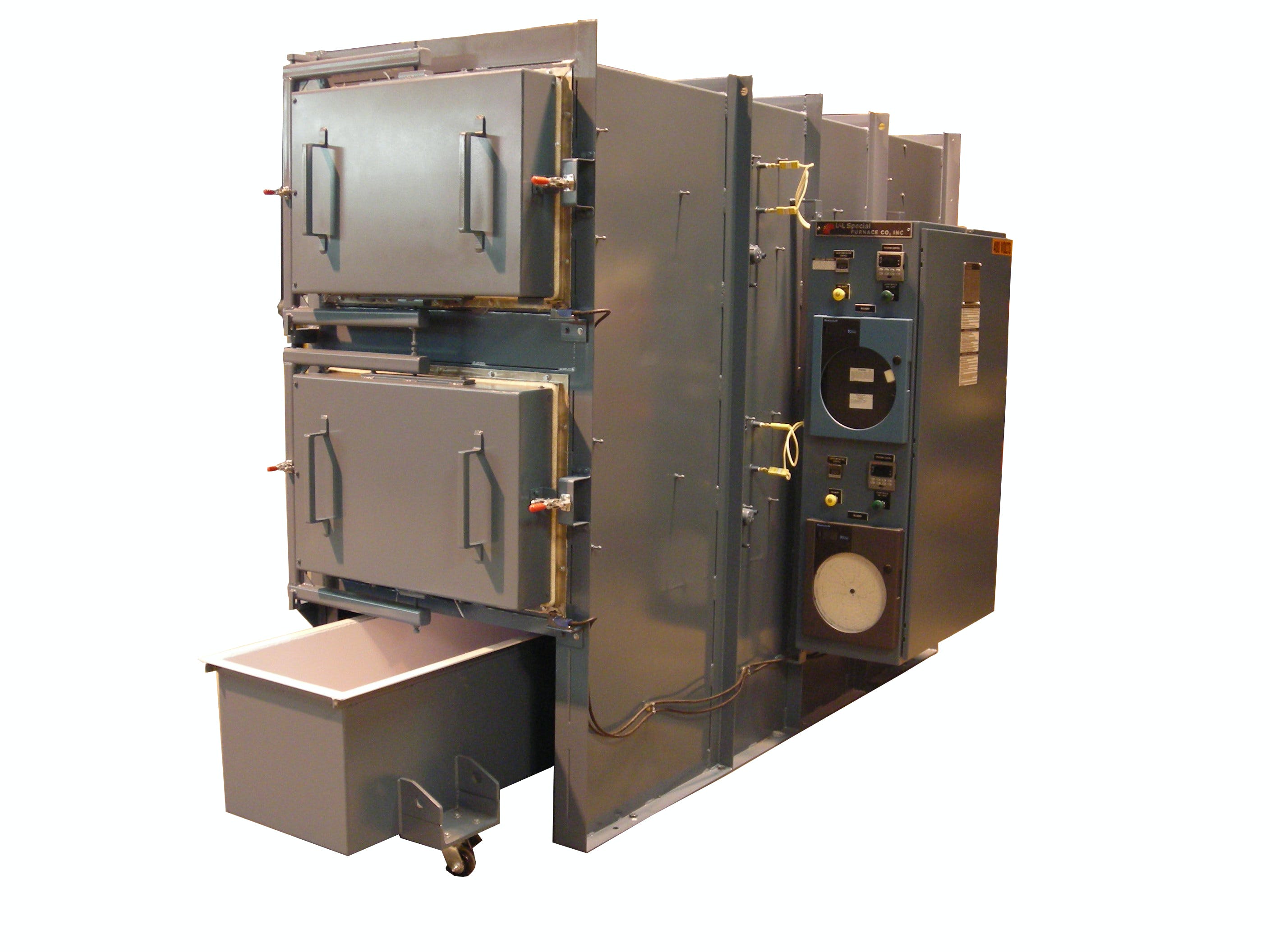

L&L Furnaces Used for Aluminum Heat Treating

- VB series of bench mounted recirculating 1300°F (700°C) tempering oven

- GS1714A from the GS series of smaller furnaces which are typically in stock for immediate shipment

- DV/DR series of heavy duty floor standing gas or electric recirculating 1300°F (700°C) tempering ovens

Aluminum Heat Treating and Compliance with AMS2750E

Contact L&L for Aluminum Heat Treating Furnaces

We hope you found this article informative and engaging. At L&L Special Furnace, we are dedicated to providing high-quality industrial furnace solutions tailored to meet your specific needs. With decades of experience and a commitment to innovation, we strive to deliver exceptional products and services to our valued customers.

For more information about our products, visit our Series page. Need help with your current heat treating solution? Contact us today to speak with an expert who can help.

Interested in working with us?

Sometimes it is easier to talk to someone directly. Provide us basic contact information. We'll be in touch